What is “Safety” ?

First up, here is what do we mean by safety

Ensuring safety in the aerospace, transportation, energy and defence sectors is crucial. It involves a team of industry experts, engineers and professionals who focus on risk management, building new systems and optimising existing ones. However, safety is a complex matter, and you’ll hear a lot of technical acronyms. In this guide, we try to explain these and make the concepts more digestible.

Air traffic management (ATM)

Air traffic management (ATM) refers to systems, procedures and human operations that administrate and govern the use of airspace and movement of aircraft. It involves the coordination and control of aircraft to ensure safe, efficient and orderly operations in the skies. ATM encompasses various elements, technologies and stakeholders. Together, their objective is to ensure safe, cost-effective, sustainable and well-organised aircraft movement.

The airspace is divided into different classes and sectors to facilitate efficient ATM deployment. Different classes of airspace have specific rules and regulations governing aircraft operations. The organisation of airspace allows for proper routing, separation of traffic and allocation of resources based on the volume and type of traffic.

Air traffic control (ATC) plays a central role in ATM. ATC controllers provide instructions to pilots, including clearances, routing and separation instructions to maintain safe distances between aircraft.

ATM also involves a process called air traffic flow management (ATFM) – the strategic planning and management of air traffic to ensure efficient utilisation of airspace and airport capacity.

The ASM (airspace management) component of ATM aims to manage the airspace as efficiently as possible for its users. In this case they can be both civil and military. ASM concerns both the way airspace is allocated to its different users (routes, zones, flights etc.) and the way in which it is structured to provide air traffic services.

Effective communication, navigation and surveillance systems are also vital components of ATM. Communication systems, such as radio and data links, enable seamless communication between pilots and air traffic controllers.

Overall, efficient air traffic management is vital to ensuring the safety, capacity and sustainability of the aviation system. Continuous innovation and improvement in ATM practices is essential. Technologies like automation systems, data processing and analysis tools, advanced communication systems and real-time information-sharing platforms are playing a crucial role in enhancing ATM capabilities, while data link communications, satellite-based navigation, and predictive modelling enable more efficient and precise air traffic management.

Unmanned aircraft system traffic management (UTM)

Unmanned aircraft system traffic management (UTM) is a framework and set of technologies designed to manage the increasing number of unmanned aircraft systems (UAS), such as drones, eVTOL etc. operating in the airspace. Its ultimate aim is to enable their widespread use while maintaining the current level of airspace safety.

UTM provides a means to integrate UAS into the airspace alongside manned aircraft. It involves developing rules, procedures and technologies that enable UAS to operate safely and efficiently while ensuring a seamless integration with manned aviation. UTM focuses on managing the increased complexity of UAS operations. It incorporates methods to identify and track UAS in real-time.

Moreover, UTM provides services and platforms that support UAS operators in planning and conducting their flights safely. These services can include flight planning tools, airspace restrictions and notifications, dynamic airspace configuration, weather information and access to real-time data on manned aircraft traffic. UAS operators can use these services to make informed decisions and comply with regulations.

UTM is a critical enabler for the safe and efficient operation of UAS in a complex airspace environment. Through effective UTM implementation, the potential of UAS can be fully realised while maintaining safety and security in the airspace.

Model-based systems engineering (MBSE)

MBSE stands for model-based systems engineering. It emphasises the use of models to design, analyse and manage complex systems throughout their lifecycle. MBSE aims to improve communication, collaboration and understanding among stakeholders involved in the development and operation of a system.

In MBSE, various models represent different aspects of the system being developed. These can include functional models, behavioural models, structural models, requirement models and more. These models capture the system’s requirements, architecture, behaviour and other relevant information, providing a visual representation that can be easily understood and shared among team members.

The key idea behind MBSE is that by using models, system engineers can better understand the system’s behaviour, verify and validate requirements, identify design issues early in the development process, and facilitate system integration and testing. Models can be simulated, analysed and modified to assess different design alternatives, evaluate system performance, and ensure that the system meets its intended goals and requirements.

By adopting MBSE, organisations can benefit from improved system understanding, enhanced collaboration, reduced errors and enhanced traceability throughout the system development lifecycle. It helps address the complexity and interdependencies of modern systems, supporting better decision-making and ultimately leading to more efficient and effective system development.

Model-based safety assessment (MBSA)

Model-based safety assessment/analysis (MBSA) is an engineering technique used to assess and analyse the safety of complex systems or products using computational models. It leverages the power of modelling and simulation to identify potential hazards, analyse safety risks and evaluate the effectiveness of safety measures throughout a system’s lifecycle.

The primary purpose of MBSA is to support the identification, analysis and mitigation of safety-related risks in complex systems. It allows engineers to simulate and analyse system behaviour, interactions and failure scenarios in a virtual environment, enabling them to identify potential hazards and evaluate safety measures before physical implementation.

MBSA relies on the development and utilisation of computational models that represent various aspects of a system, including its structure, behaviour, functionality and safety-related attributes. These models can range from simple block diagrams to more sophisticated models based on mathematical equations, logic or simulation tools.

MBSA is most effective when integrated into the overall system design process. It allows engineers to consider safety aspects early in the design phase, facilitating the implementation of safety features at the conceptual and detailed design stages.

MBSA often involves collaboration between multiple engineering disciplines and stakeholders, as it requires the exchange of data and information between different models and tools. Effective collaboration and data exchange mechanisms are essential for successful MBSA implementation.

However, it’s important to note that MBSA should be used in conjunction with other safety assessment techniques and should not replace physical testing or real-world verification. It serves as a valuable tool in the safety assessment toolkit, complementing traditional methods and enhancing the overall safety engineering process.

Interested in our MBSA tool? Check out more information here.

Design Organisation Approval (DOA)

A Design Organisation Approval (DOA) is an agreement granted by regulatory authorities to an organisation involved in the design of aircraft, aeronautical products or major modifications. It authorises the organisation to carry out design activities within the scope of the approval. A DOA is a mandatory certification for companies engaged in designing and modifying aircraft.

The primary purpose of a DOA is to ensure that the organisation’s design processes and procedures comply with regulatory requirements and meet the necessary safety standards. A DOA demonstrates that the organisation has the capability, competence and resources to design and modify aircraft and aeronautical products safely and reliably.

To obtain a DOA, the organisation must establish and maintain robust design procedures. These cover various aspects of design, such as concept development, analysis, testing, verification, validation, documentation and configuration control. The organisation must adhere to established design standards, regulations and guidelines throughout the design lifecycle.

Each DOA is granted by the airworthiness authority responsible for aviation safety oversight, such as the European Union Aviation Safety Agency (EASA) in Europe or the Federal Aviation Administration (FAA) in the United States. The airworthiness authority assesses the organisation’s design capabilities, processes, and quality management systems before granting it. The airworthiness authority monitors as well the same processes though regular audits, inspections and surveillance.

Having a DOA has several benefits. It streamlines the certification process for new aircraft designs or modifications, as the organisation can issue design approvals and certificates directly without relying on individual certification from the airworthiness authority. It also offers greater flexibility and control over the design process, enabling quicker response times and reduced time-to-market for new products or modifications.

In summary, Design Organisation Approval certifications play a critical role in ensuring that aircraft and aeronautical products are designed and modified in accordance with established safety standards and regulatory requirements.

Safety management system (SMS)

A safety management system (SMS) is a structure designed to proactively manage safety risks and ensure the highest level of safety in an organisation’s operations. It provides a systematic framework for identifying, analysing, and mitigating hazards and risks associated with an organisation’s activities, products or services.

The primary goal of an SMS is to foster a ‘safety culture’ and create an environment where safety is prioritised and continuously improved. It goes beyond mere compliance with regulations and standards by encouraging a proactive and data-driven approach to safety management.

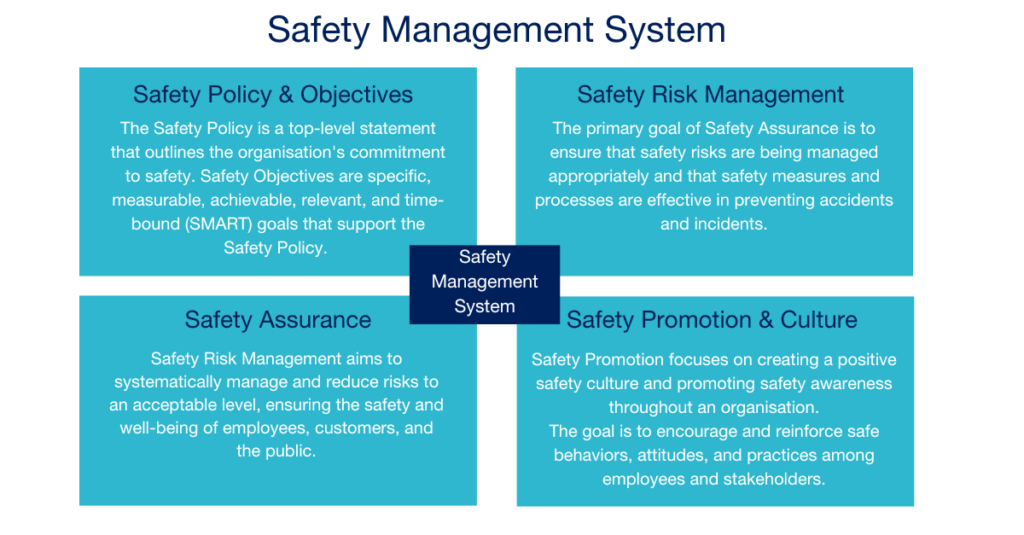

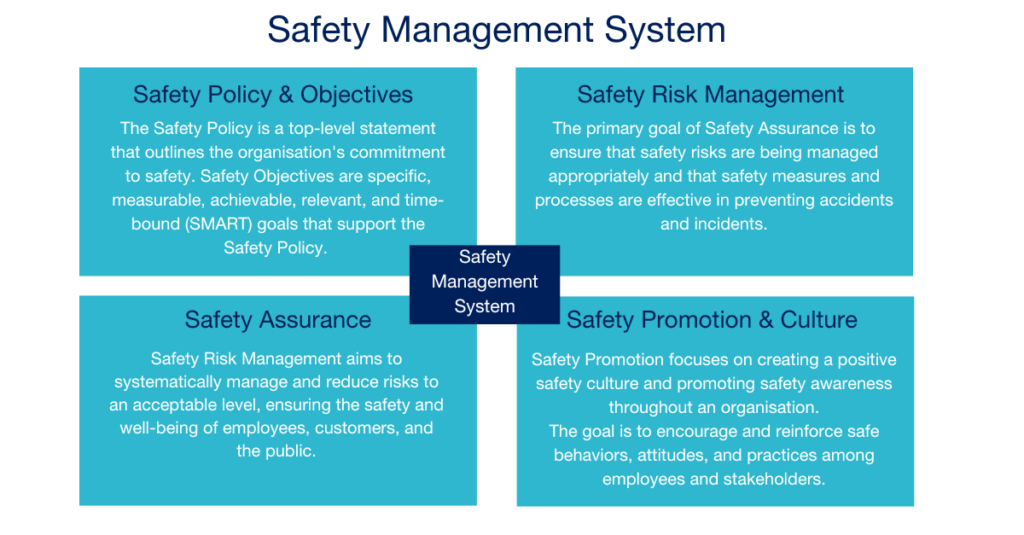

A robust SMS maintains documentation and records of safety-related information. The four main components of the SMS are the Safety Policy & Objectives, Safety Assurance, Safety Risk Management and the Safety Promotion. This includes safety policies, procedures, risk assessments, incident reports, safety performance data, training records and other relevant documentation. Accurate and up-to-date records are essential for analysis, audits and compliance purposes.

The Safety Policy is a top-level statement that outlines the organisation’s commitment to safety. It is typically established by senior management and serves as the foundation for the entire SMS. It should be clear, concise, and accessible to all employees.

Safety Objectives are specific, measurable, achievable, relevant, and time-bound (SMART) goals that support the Safety Policy. These objectives help organisations to focus on areas that require improvement and track their progress.

Safety Assurance involves the systematic monitoring, evaluation, and verification of safety performance as well as the effectiveness of safety risk controls within an organisation. The primary goal of Safety Assurance is to ensure that safety risks are being managed appropriately and that safety measures and processes are effective in preventing accidents and incidents.

Safety Risk Management requires identifying, analyzing, assessing, and mitigating safety risks in order to prevent accidents, incidents, and other safety-related events. It aims to systematically manage and reduce risks to an acceptable level, ensuring the safety and well-being of employees, customers, and the public.

Safety Promotion focuses on creating a positive safety culture and promoting safety awareness throughout an organisation. It involves various activities and initiatives designed to encourage and reinforce safe behaviors, attitudes, and practices among employees and stakeholders.

SMS is dynamic – it promotes continuous improvement in safety performance. Organisations should regularly review and evaluate their safety management systems, learn from incidents and near-misses and implement corrective actions to address identified deficiencies.

It’s important to note that SMS implementation can vary by industry. For example, industries such as aviation, maritime, and oil and gas often have specific regulations and standards that guide the development and implementation of SMS.

By implementing a safety management system, organisations demonstrate their commitment to safety, reduce the likelihood of accidents and incidents, protect personnel and assets, enhance operational efficiency and improve overall safety.

‘Reliability, Availability, Maintainability and Safety’ (RAMS)

RAMS, short for ‘Reliability, Availability, Maintainability and Safety’, is an engineering technique which ensures that complex systems or products are designed, built, operated, and maintained in a way that meets the required levels of reliability, availability, maintainability, and safety throughout their lifecycle. RAMS focuses on managing and optimising these four key aspects to enhance the overall performance and effectiveness of a system.

Here’s a quick breakdown of each:

- Reliability: Reliability refers to a system’s ability to perform its intended function without failure for a specified period under given conditions. It involves assessing the probability of failure, mean time between failures (MTBF) and other reliability metrics. Engineers employ various techniques like reliability modelling, testing, and analysis to identify potential failure modes, estimate failure rates and improve the system’s overall reliability.

- Availability: Availability is the measure of a system’s ability to be operational and accessible when needed. It considers both the uptime and downtime of a system, aiming to maximise the former while minimising the latter. Availability analysis involves evaluating factors such as system design, redundancy, fault tolerance, maintenance strategies and repair time to ensure the system remains available as required.

- Maintainability: Maintainability focuses on designing systems that are easy to maintain and repair. It involves minimising downtime and reducing the time, effort and resources required for maintenance activities. Factors considered in maintainability include accessibility of components, ease of troubleshooting, diagnostic capabilities, modularity and the availability of spare parts. Effective maintainability practices contribute to shorter repair times and increased system availability.

- Safety: Safety pertains to the prevention of hazards, accidents and risks associated with a system throughout its lifecycle. It involves identifying potential hazards, assessing risks and implementing safety measures to minimise or eliminate them. Safety considerations encompass design features, materials, protective systems, fail-safe mechanisms, warning signs, and adherence to relevant safety standards and regulations.

RAMS engineering techniques involve a range of methodologies, tools, and analyses, such as fault tree analysis, failure modes and effects analysis (FMEA), reliability-centred maintenance (RCM), hazard analysis, probabilistic risk assessment (PRA) and safety integrity level (SIL) determination. These techniques help engineers identify potential issues, evaluate risks, make informed design decisions and establish improvement strategies.

Integrating RAMS principles into design, operation and maintenance processes enables engineers to enhance the performance, efficiency and safety of complex systems. This is crucial in transportation networks, industrial facilities, power plants, aerospace systems and other critical infrastructure.

Want to learn more at Airbus Protect’s summer school? Check out insights on these topics:

Safety

Safety