From Ambition to Reality: Securing Europe’s Aviation Fuel Supply with Sustainable Aviation Fuel

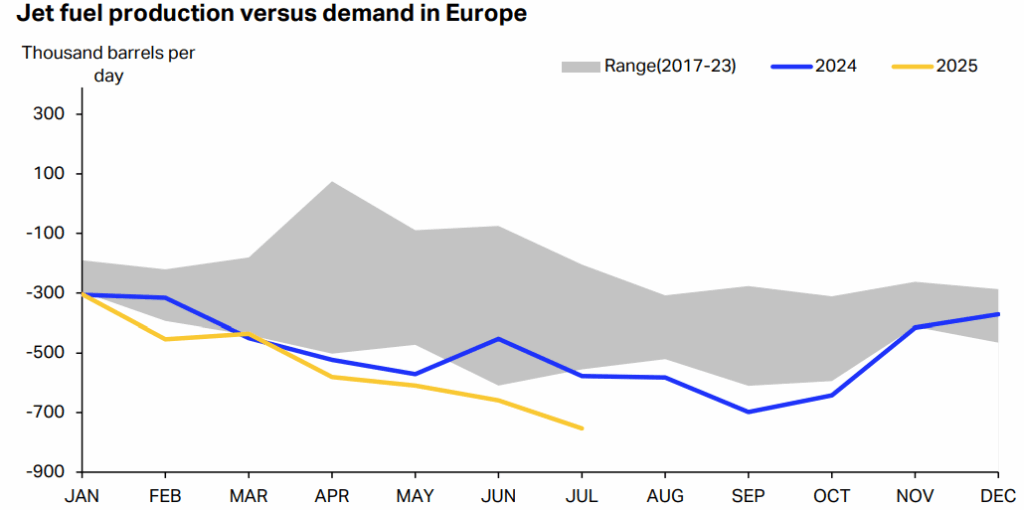

The past few years have been a stark reminder that energy security is not a given. For aviation, a sector historically dependent on globally-sourced fossil fuels, this reliance represents a critical vulnerability. As IATA has highlighted, Europe’s own jet fuel deficit continues to widen, increasing its dependence on imports and exposing the continent to significant supply chain and price volatility. The first EASA ReFuelEU technical report, based on 2024 data, further underscores the urgency: the EU supplied just 0.60% sustainable aviation fuel (SAF), leaving a massive gap to climb to meet the mandatory 2.0% blend required for 2025. (https://www.easa.europa.eu/en/document-library/general-publications/refueleu-aviation-annual-technical-report-2025)

This vulnerability is poised to enter a new phase. Without a robust domestic SAF industry, Europe risks simply trading its dependency on fossil fuel imports for a new dependency on foreign-produced green fuels. The EASA report reveals that in 2024, Europe was heavily reliant on foreign sources, importing 69% of the feedstock for its SAF. China alone supplied 38% of this feedstock. On top of this, over 40% of the final, refined SAF was also imported.

Nations like China are already moving decisively, with state-supported production expanding rapidly and new government quotas positioning them as major SAF exporters. This means SAF production is not only a climate imperative; it’s a strategic one, fundamental to the continent’s economic and industrial autonomy, and securing a stable, domestic supply of Sustainable Aviation Fuel is an achievable target.

The policy engine: From “Fit for 55” to market certainty

This transition is being actively driven by robust policy. The EU’s ReFuelEU Aviation initiative, a cornerstone of the “Fit for 55” package, is the primary engine. It provides the long-term market certainty needed to unlock massive private investment. By mandating progressively increasing SAF blends, starting at 2% in 2025 and rising to 70% by 2050, it de-risks multi-billion-euro investments in new refineries by guaranteeing decades of future demand.

The UK is moving in lockstep, introducing its own ambitious SAF mandate that also began in 2025, targeting 10% SAF use by 2030 and 22% by 2040. Crucially, the UK mandate includes a specific sub-target for Power-to-Liquid (e-kerosene) fuels, signaling a clear commitment to scaling this long-term solution.

To kickstart this domestic industry, the mandate is supported by an industrial investment mechanism: the Advanced Fuels Fund. This fund provides critical grant funding to de-risk and bridge the formidable investment gap for first-of-a-kind (FOAK) commercial and demonstration-scale SAF plants, moving them from the lab to commercial reality.

These policies, in concert, are not just environmental regulations. They are powerful industrial strategies designed to build a new, high-value European industry, create thousands of skilled jobs, and secure the continent’s leadership in green technology.

The two-pronged approach to production

To meet these mandates, Europe is mainly focusing on a two-pronged production strategy:

- Bio-SAF: Biomass-based Sustainable Aviation Fuel (SAF) is the most commercially mature pathway available today, utilising feedstocks such as used cooking oil (UCO), animal fats, and agricultural residues. It’s the critical bridge to meeting our 2030 goals. However, the competition for these feedstocks is already intense. The road transport and chemical industries are vying for the same limited pool of waste oils, driving up costs and creating supply chain pressures. Its long-term growth potential in Europe, while significant, has a ceiling.

- Power-to-liquid / e-kerosene: This is the true north for aviation’s energy independence. By combining captured CO₂ with green hydrogen (produced using renewable electricity), e-SAF offers a scalable, high-integrity path to decarbonisation that is not constrained by biomass availability. This pathway, however, demands a parallel, massive build-out of renewable energy infrastructure. This means an expansion of wind, solar farms, and nuclear power, which compete for land and investment with other high-demand sectors like data centres. Achieving viability at scale also requires major investment in infrastructure like grid stabilisation and hydrogen electrolysis plants. Finally, it necessitates developing and deploying CO₂ capture technologies, either from industrial sources or Direct Air Capture (DAC). The EASA report issues a stark warning: the scale-up of e-SAF is “lagging,” and not a single commercial facility in the EU has reached a Final Investment Decision (FID). This underscores the immense engineering and investment challenge ahead.

The real bottleneck: Industrialising at scale

For years, the debate has centred on feedstock availability. A recent IATA study decisively settled this, concluding that sufficient sustainable feedstock does exist to meet our 2050 net-zero goals. The real challenge is not one of availability, but one of industrial scale-up. (https://www.iata.org/en/publications/economics/reports/global-feedstock-assessment-for-saf-production/)

As IATA’s Director General, Willie Walsh, stated, “If SAF production is prioritised… feedstock availability is not a barrier… However, this will only be accomplished with a major acceleration of the SAF industry’s growth. We need shovels in the ground now.”

This is the crux of the issue. “Shovels in the ground” means moving from small pilot projects to building and operating multiple full-scale commercial refineries. We are not just creating a new fuel; we are building an entirely new industrial ecosystem from the ground up. This includes new certified logistics chains, new blending facilities at airports, a newly skilled workforce, and entirely new regulatory frameworks, all on an accelerated timeline.The EASA report confirms the goal is achievable: its optimistic projection for EU production capacity by 2030 is 5.2 million tonnes, well above the 2.2 million tonnes required for the main 2030 mandate.

Navigating the transition: From complex risk to industrial reality

Scaling an entire industry while managing the phase-out of another is fraught with complexity. This transition introduces profound industrial, safety, and engineering challenges that must be managed with precision.

- For bio-SAF: How do we secure, certify, and manage complex global supply chains for sustainable feedstocks? This goes beyond logistics; it requires robust auditing to prevent feedstock fraud and ensure strict sustainability criteria are met from source to refinery.

- For e-SAF: How do we safely design, build, and operate novel, high-pressure hydrogen production and carbon capture facilities? These plants involve significant processes for safety risks, such as handling high-pressure or cryogenic hydrogen, and are often co-located with existing carbon-intensive industries like cement or steel, adding layers of integration risk.

- For infrastructure: How do we adapt or repurpose existing refineries and airport logistics to safely handle, blend, transfer, and store these new fuels? This involves detailed engineering studies to ensure material compatibility with existing pipelines and storage tanks and to design safe, efficient blending operations. And how do we build a resilient distribution network when 99% of all SAF used in the EU in 2024 was delivered to just five Member States?

- For all: How do we ensure the digital infrastructure managing these new energy grids and supply chains is secure from cyber threats? A cyber-attack on a plant’s Operational Technology (OT) could halt production, or an attack on the blending logistics network could ground flights, turning a digital vulnerability into a critical physical disruption.

These are not abstract questions. They are the concrete engineering, safety, and regulatory hurdles that operators, investors, and infrastructure partners face today.

How Airbus Protect enables the SAF transition

This is precisely where Airbus Protect provides critical value. As the Airbus-wide partner for safety, cybersecurity, and sustainability, we are at the forefront of managing the complex risks of this industrial transition. Our role is to ensure that this rapid scale-up is achieved safely, securely, and efficiently.

We partner with companies across the aviation and energy ecosystem to:

- Engineer industrial safety: Our deep expertise in industrial safety processes is essential for operators building new e-SAF or hydrogen plants. We develop the safety cases, identify ways to mitigate operational risks, and ensure the safe integration of these new, complex technologies.

- Manage risk & compliance: We guide clients through the evolving web of regulations, from ReFuelEU and UK Mandate compliance to certifying new feedstock supply chains, ensuring their pathway to SAF is both sustainable and compliant.

- Deliver energy transition expertise: Our engineers provide the technical guidance to make the transition a physical reality. This includes advising on the safe repurposing of existing industrial facilities, assessing the integration of new fuels into airport infrastructure, and managing the unique risks of the hydrogen lifecycle.

- Secure the digital backbone: This new energy ecosystem is digitally dependent. Our cybersecurity teams work to secure the operational technology (OT) and IT systems that manage everything from renewable energy grids to fuel-blending logistics, protecting critical infrastructure from attacks.

Achieving energy security in aviation is not a distant dream; it is an industrial and engineering challenge that is being solved today. The mandate is set, the technology is known, and the feedstocks are available. Now is the time to build, and Airbus Protect is the trusted partner to ensure we build it safely, securely, and sustainably.

Learn more about our sustainability portfolio here.

- Share